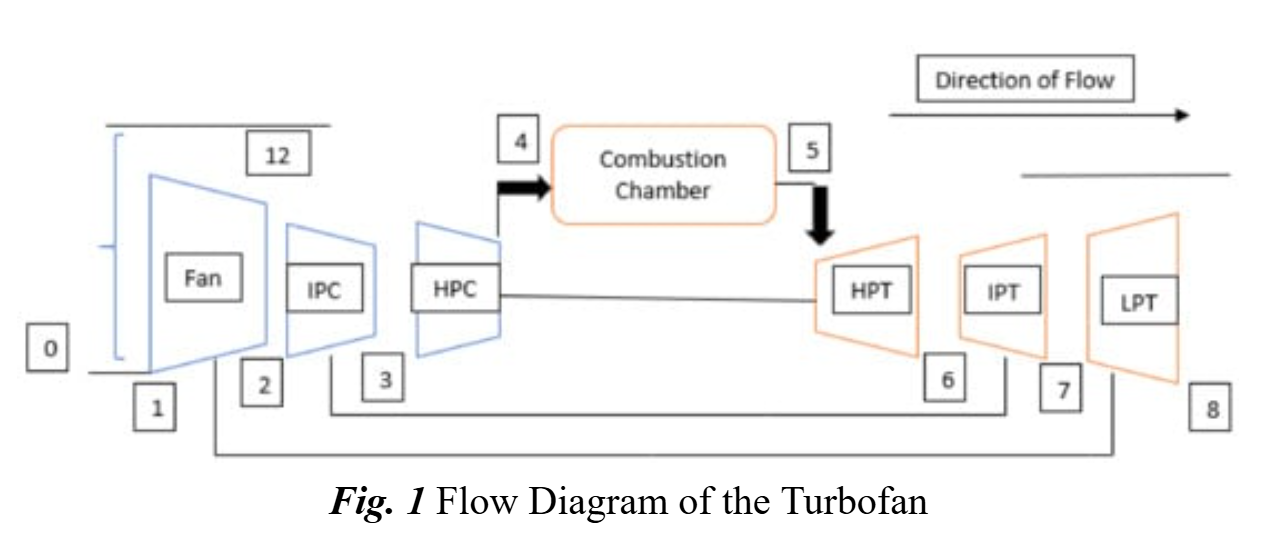

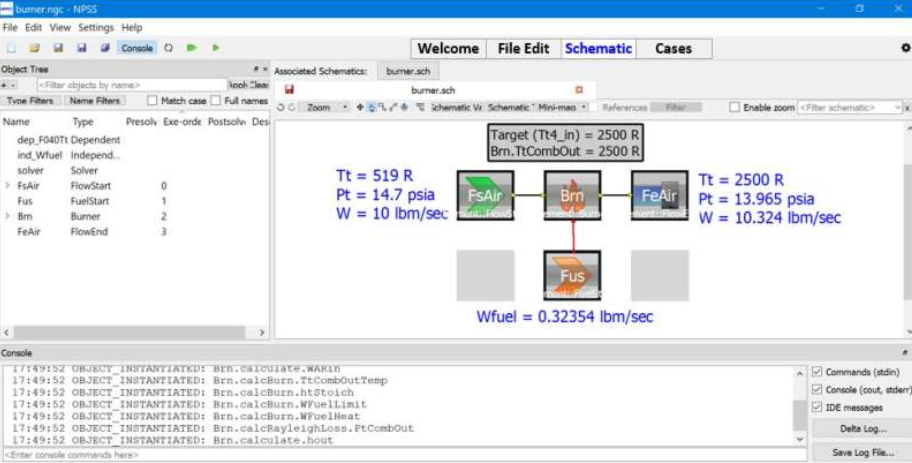

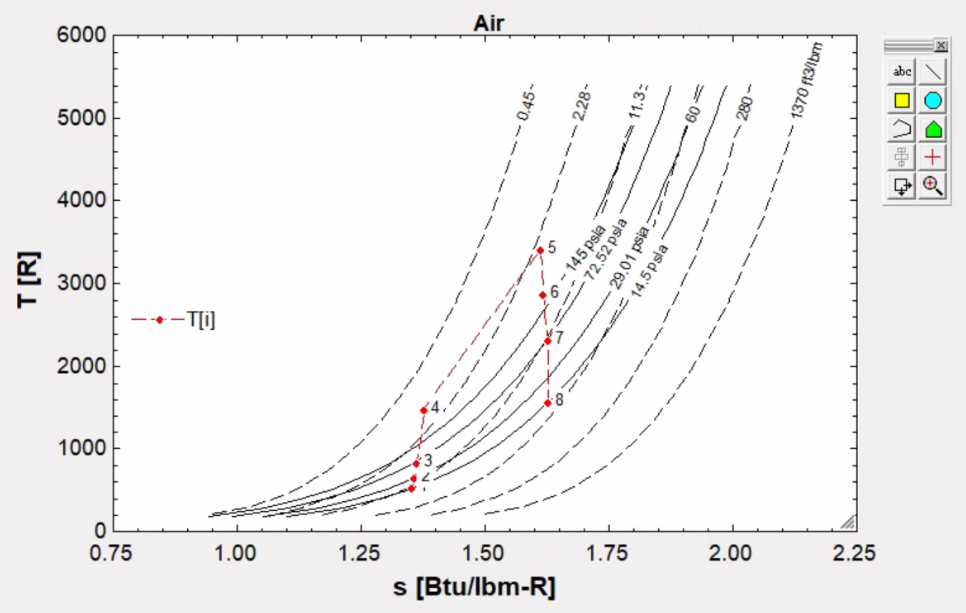

The engine components, such as the bypass, inlet, compressors, combustion chamber, turbines, and nozzle, were simulated using the mathematical model that combined empirical correlations with thermodynamic principles. While maintaining accuracy, the model was made simpler by making assumptions about ideal gas behavior and steady-state functioning.